WHAT'S NEW

THE LATEST HEADLINES

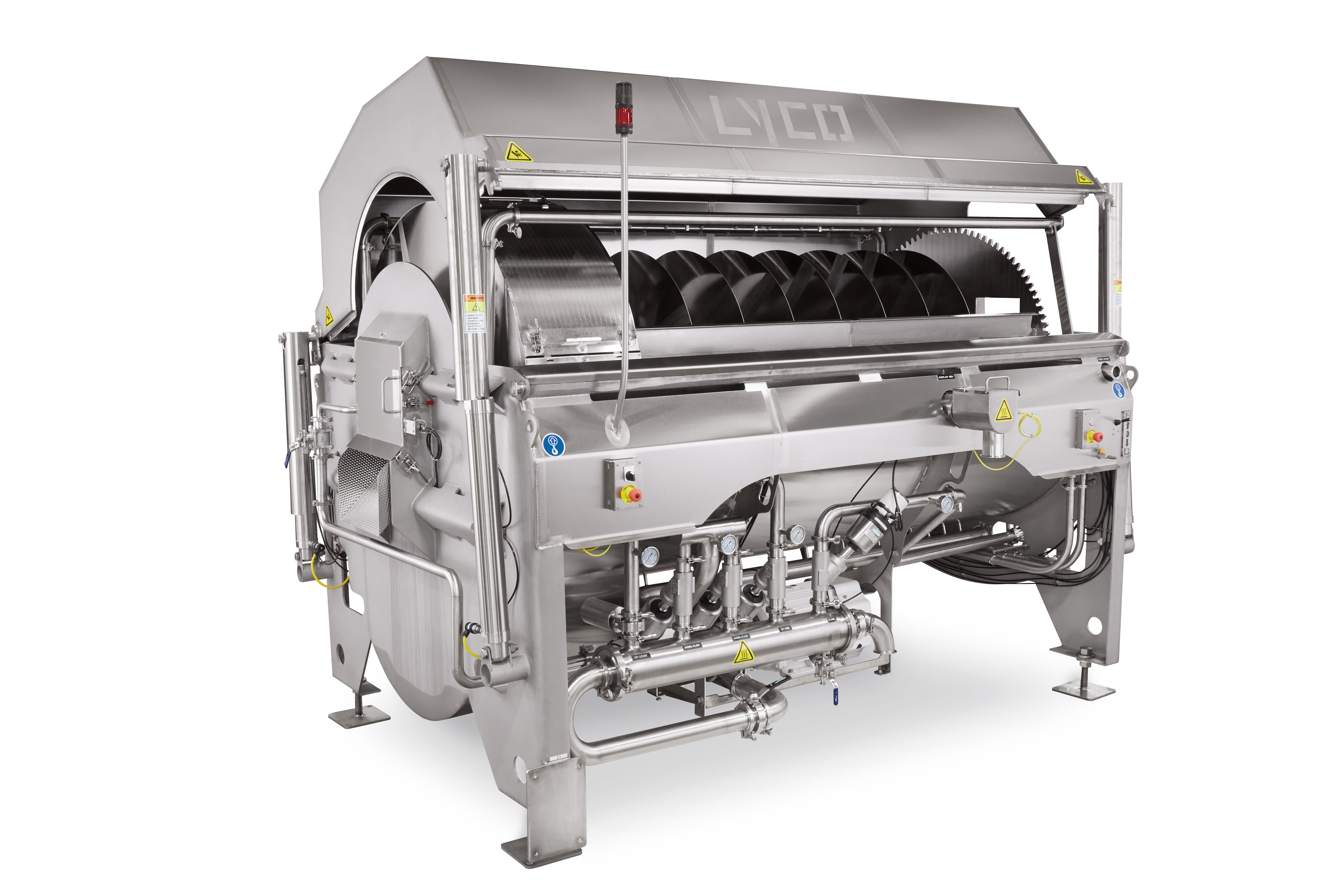

Clean-Flow® Blanchers for pasta, rice & vegetables called “The best in the world” by Mr. Tops in Belgium.

Easy-Flow™ Continuous Coolers cool most pastas or diced vegetables in 30 seconds or less.

Chill-Flow™ Rotary Drum Pouch Coolers that can cool pizza sauce, soups and more 40% faster than belt coolers.

Lyco Internally Fed Wastewater Screens (.020″) are the most effective in the world. They are proven as the most rugged, low maintenance design on the market.

New External Flow Wastewater Screens are ideal for Pork, Beef, Pet Food, and Further Processing meat plants with a lot of fats,oils, and grease.

Lift and Dump all electric tote dumper.

Sanitary Zero Maintenance Screen.

Water Reuse.