THE EXPERTS

IN INNOVATIVE

FOOD PROCESSING

MACHINERY

IN INNOVATIVE

FOOD PROCESSING

MACHINERY

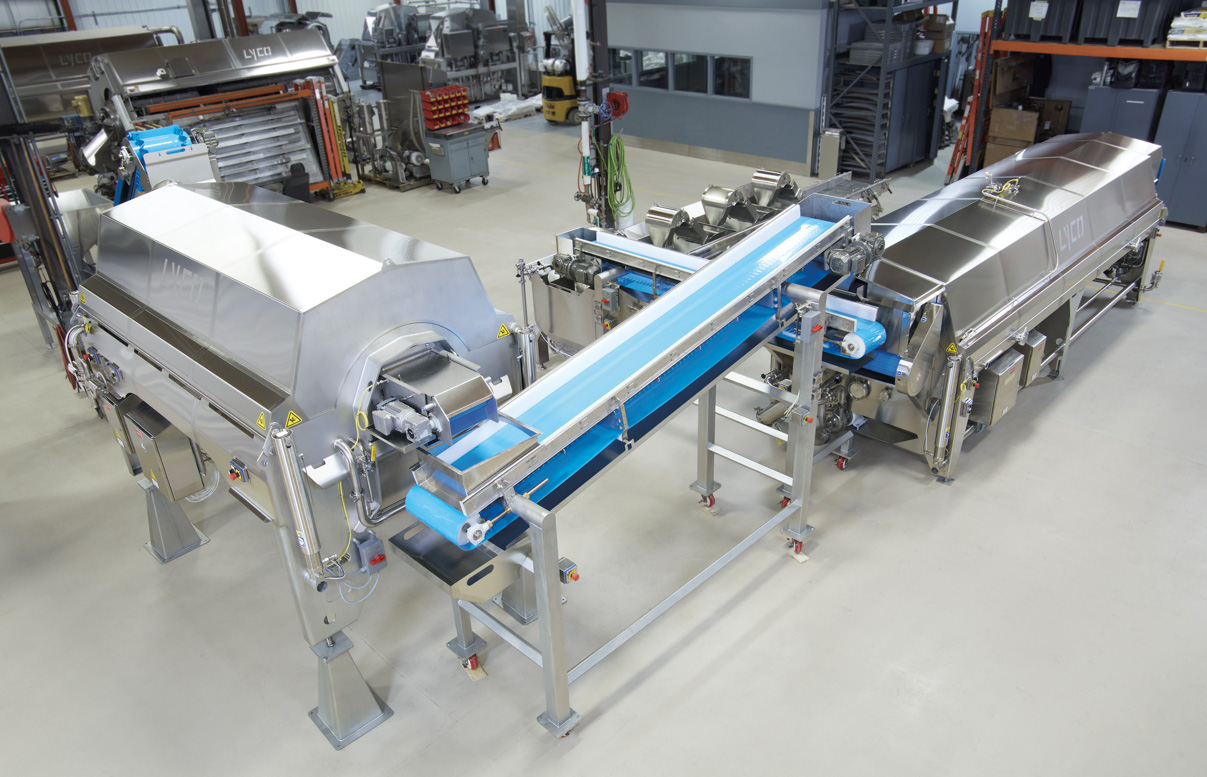

We design and manufacture blanching, cooking, cooling and wastewater equipment that solve supply chain gaps, production challenges, capacity issues and labor shortages for leading food processors.

MORE THAN MACHINERY - LYCO SERVICES

-

Add automation and new technologies for improved results

-

Hands-on evaluation of our food processing technology at your facility

-

Lyco Audits provide customers with expert on site inspections

-

Highest quality, OEM parts with prompt shipping

-

We provide on-site training and commissioning

-

40 years of proven support to get you up and running quickly

-

Develop and prove your process prior to making the investment

-

New equipment and refresher training for optimal results