Perfect for rendering operations, this system effectively applies heat to extract moisture and separate fat, producing superior crax to the press versus a perk pan, to create rich, granular meals for animal feed or other industrial use.

Wedge wire screens capture more solids with .020″ spacing than round hole perforated screens. This reduces insoluble impurities and avoids screens and other equipment further down the processing line.

|

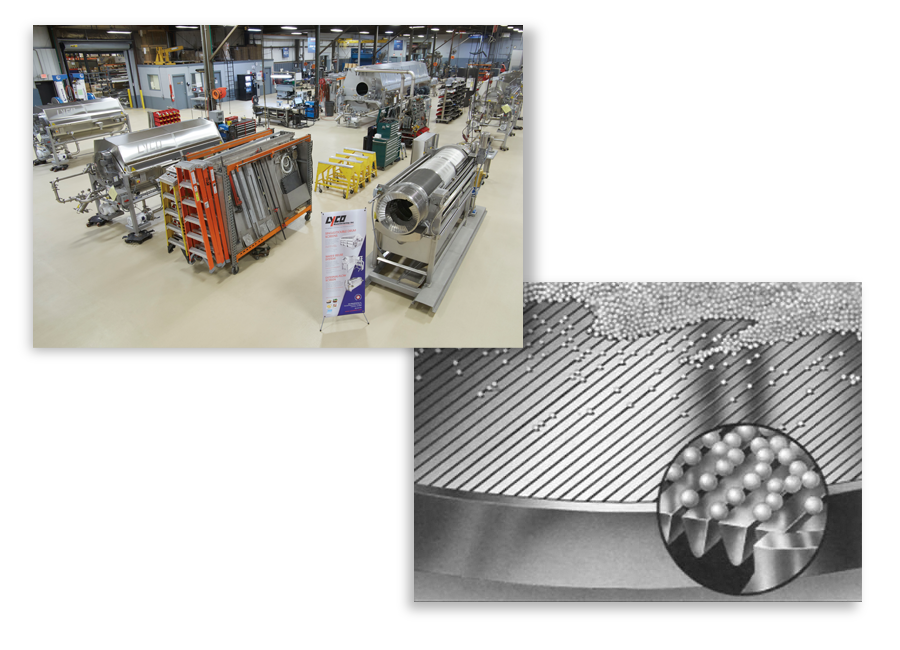

Lyco was founded in 1980 by the owner and Chairman of the Board, David R. Zittel, who had over 50 years experience in food processing. Lyco prides itself in the longevity of its associates and is measured with many decades of experience with food processing machinery. We’re located in a community of 5,000 people which is 25 miles northeast of Madison, WI, a perfect area to raise a family.

Lyco’s enjoyment and passion is developing the best customer-aligned, innovative food processing machinery in the world. |

Easy maintenance – unique, two-way flip top

Easy cleaning – multiple clean-in-place (CIP) systems

Wedge-wire screens bind less compared to perforated plates and

Reduce impurities – solids removal down to 0.020