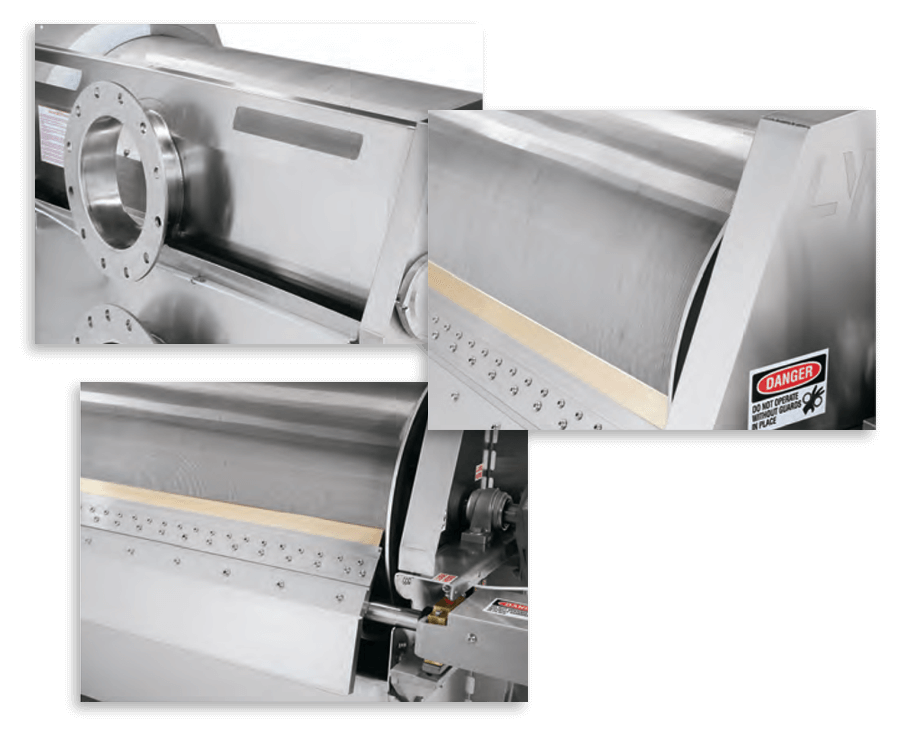

The state-of-the-art design of the Lyco External-Flow Screen uses Lyco’s advanced technology and precision manufacturing to help our customers improve their operations for further processing plants, or beef and pork harvest plants with a lot of fat or greases.

The externally fed screen fits this application better than internally fed or stationary screens. Each design is built with exacting precision and heavy-duty construction for long life and low maintenance.

Doctor Blade – This helps remove solids from the screen while turning for effective cleaning and to reduce binding.

Wedgewire Screen Construction – Wedgewire is more efficient and less apt to plug than a perforated plate. Openings can vary between .030” to .060”.

Headbox with Overflow – In addition to overflow protection, Lyco screens also come with clean-out ports for easier cleaning and inspection.

|

Lyco was founded in 1980 by the owner and Chairman of the Board, David R. Zittel, who has had over 50 years experience in food processing. Lyco prides itself in the longevity of its associates and is measured with many decades of experience with food processing machinery. We’re located in a community of 5,000 people which is 25 miles northeast of Madison, WI, a perfect area to raise a family.

Lyco’s enjoyment and passion is developing the best customer-aligned, innovative food processing machinery in the world. |

2. As the drum rotates, it pulls solids to the outside of the screen where a blade removes the solids.

3. The water is screened as it passes through, and cascades down the inside of the drum, creating backwash.

4. The backwash, inner spray header, and internal flights work in tandem to self-clean the drum.

THE PROBLEM

Food processors need to find ways to lower BOD, TSS, and TKN, while also reducing their hauling costs and achieving higher recovery.

THE SOLUTION

The Doctor Blade, Wedgewire Screen Construction and Headbox with Over-Flow Protection combine to deliver lower wastewater handling costs and increased product recovery.

• Proven rugged, low-maintenance construction

• Lower BOD, TSS, and TKN with reduced hauling costs and higher recovery

• Uses less chemicals in post-water treatments

• Control panel option for easy startup

• Cleanout ports for easy sanitation

• Continuous internally-reinforced drum for precise roundness

• TEFC variable heavy-duty Nord Gear drive

• Optional solenoid valve