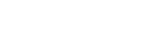

Lyco LAD Lift and Dump Systems help producers meter and feed their blanchers and cookers with increased precision. The two-stage “Lift and Dump” is a floor loading system with an overall height that is adjustable to the ceiling.

FLOOR LOADING

• Overall height adjustable

• Forklifts for pallet jacks loading

• Adjustable tote hold down bars

• Safety sensors at loading station

SANITARY ACCURATE FEED SYSTEM

• Large Hopper to accommodate full tote

• Electro magnetic even feed conveyor

• Handles all short goods dry pasta shapes

• Infinite other particulate food types

• Precisely meter feeds Blanchers/Cookers

|

Lyco was founded in 1980 by the owner and Chairman of the Board, David R. Zittel, who had over 50 years experience in food processing. Lyco prides itself in the longevity of its associates and is measured with many decades of experience with food processing machinery. We’re located in a community of 5,000 people which is 25 miles northeast of Madison, WI, a perfect area to raise a family.

Lyco’s enjoyment and passion is developing the best customer-aligned, innovative food processing machinery in the world. |

Next generation – modern clean design

Sanitary design – all t-304 stainless steel

Heavy duty – robust construction throughout

Quiet – electric motor/jackscrew power

Low maintenance – runs like a clock

No leakage – no hydraulics, pumps or motors

Hinged side panels – east access to clean

Personnel safety – electric eye sensors