Clean-Flow® Blanchers were developed in 2007 to address the need for faster sanitation cleanup time so that prepared meal operations could run many different products in a day. Customers say this design is “The best pasta and rice cooker in the world!”

• Increase recovery 10% to 15%, as compared to European cook-quench-chill systems

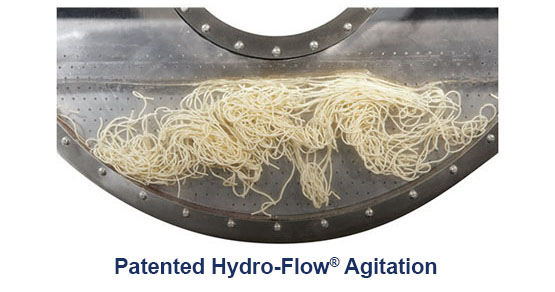

• Features Hydro-Flow® agitation, which guarantees a uniform process

• Eliminate under and over-cooking of pasta

• Fully automated

Lyco’s Clean-Flow is the most sanitary designed cooker, blancher, or cooler in the world.

The unit was designed for RTE standards, and is ideal for low care/high care cooking and cooling solutions.

Clean-Flow is 95% self-cleaning and designed for quick changeovers.

During CIP, a large gear simultaneously rotates the auger, wedge-wire screen, and discharge wheel repeatedly until the system is clean inside and out.

|

Lyco was founded in 1980 by the owner and Chairman of the Board, David R. Zittel, who has had over 50 years experience in food processing. Lyco prides itself in the longevity of its associates and is measured with many decades of experience with food processing machinery. We’re located in a community of 5,000 people which is 25 miles northeast of Madison, WI, a perfect area to raise a family.

Lyco’s enjoyment and passion is developing the best customer-aligned, innovative food processing machinery in the world. |

• Designed for rapid change-over to accommodate different recipes in the same day

• Features Hydro-Flow® agitation for uniform processing

• Easy-Flow coolers can cool, quench and chill most pasta shapes from 200ºF down to 40ºF in under 30 seconds

• Continuous systems are faster, simpler, easier to clean and produce much higher quality products

THE PROBLEM

Historically, cooking and cooling of pasta and rice was done in batch cookers with perforated baskets that over-cooked on the outside and under-cooked inside.

THE SOLUTION

Patented Hydro-Flow® is a method of agitation that:

• Uniformly cooks all products

• Eliminates sticking and clumping

• Increases yield by as much as 15%

• Uses much less water to run & clean