The Raging Bull is perfect for processing high volumes of root crop applications. It can perform after-steam peeling or stand-alone raw peeling. You can trust the Raging Bull for reliable performance and high-throughput whether processing seasonal crops or pulling products from climate-controlled storage.

• 8 and 10 roll models available

• 800-1,000 RPM Roll Speed

• Two way flip top cover

• Sanitary and easier to clean

• Easier to maintain, open and accessible

|

Lyco was founded in 1980 by the owner and Chairman of the Board, David R. Zittel, who has had over 50 years experience in food processing. Lyco prides itself in the longevity of its associates and is measured with many decades of experience with food processing machinery. We’re located in a community of 5,000 people which is 25 miles northeast of Madison, WI, a perfect area to raise a family.

Lyco’s enjoyment and passion is developing the best customer-aligned, innovative food processing machinery in the world. |

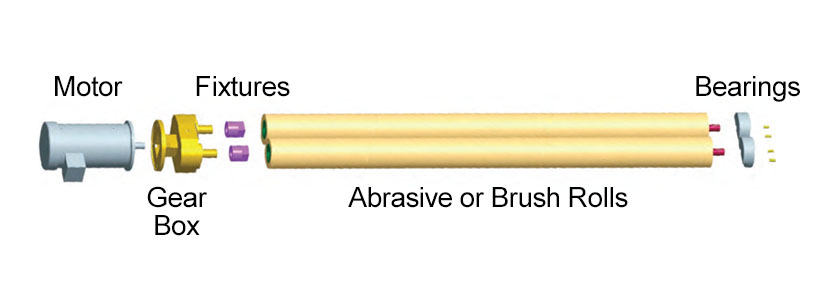

The auger raises with the cover to be open and accessible. The rugged, low-maintenance design has no chains, sprockets or gears; making it safer and reducing liability concerns. You can replace multiple scrubbers:

• Raw peel white potatoes

• Grind potatoes to “Bs”

• Scrub sweet potatoes

• Peel 6” to 9” carrots