Blancher/cooker-coolers were first designed in 1995 for cooking and cooling pasta, rice and vegetables. They have lower maintenance costs with a smaller footprint. The basic process differences between a blancher, cooker or pasteurizer are retention times and operating temperatures.

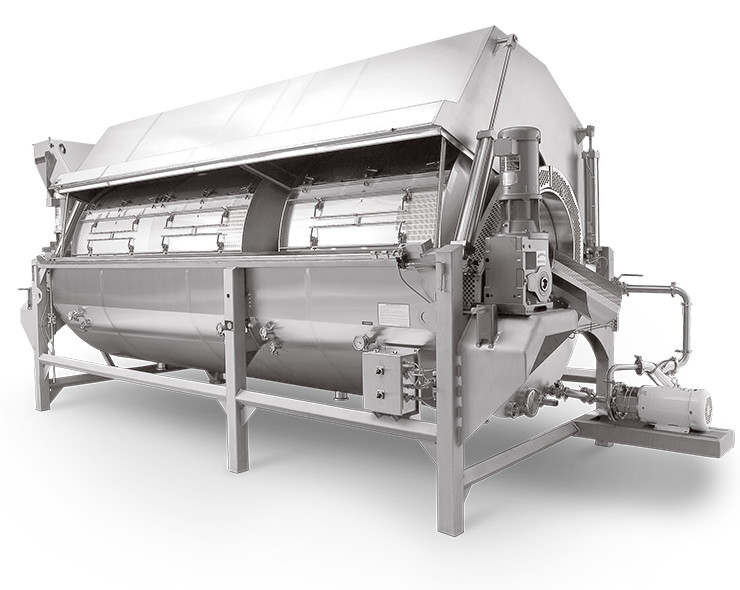

Lyco’s Cooker-Cooler is the only combination rotary drum cooker-cooler in the world, features are:

• Cook and cool in one machine

• Smaller footprint eliminates transfer conveyors, and riser frames

• The single CIP System cleans both hot and cold zones

• Uniform process results with 5-15% yield increase

• Lower initial cost and reduced maintenance

• Perfect gentle agitation eliminates pasta sticking losses

• Space saving and energy efficient

|

Lyco was founded in 1980 by the owner and Chairman of the Board, David R. Zittel, who had over 50 years experience in food processing. Lyco prides itself in the longevity of its associates and is measured with many decades of experience with food processing machinery. We’re located in a community of 5,000 people which is 25 miles northeast of Madison, WI, a perfect area to raise a family.

Lyco’s enjoyment and passion is developing the best customer-aligned, innovative food processing machinery in the world. |

The two-way flip top cover (5) can be lifted either side by simple air cylinders for easy access for cleaning.

• Agitation increases capacity by up to 50 percent and reduces losses from pasta clumping and sticking by 10 percent

• Lower maintenance costs come from fewer moving parts, precision manufacturing, and quality materials

• Trunnion designs eliminate cylinder shaft breakage

• Cylinder designs result in zero leakage