Wastewater/Process Screens

Wastewater treatment costs add up significantly for any facility — not just treatment itself but also

potential municipal costs or fines imposed for BOD, TSS and TKN*. Lyco Manufacturing offers a full line

of wastewater screens for a broad range of applications, from poultry rendering and slaughter to

vegetable processing and everything in between.

*BOD – Biochemical Oxygen Demand, or a measure of the amount of oxygen required to neutralize

organic wastes.

TKN – Total Kjeldahl Nitrogen, or the total concentration of organic nitrogen and ammonia.

TSS – Total suspended solids gives a measure of water turbidity. With TSS, values commonly expressed

in ppm (mg solids per liter of water).

-

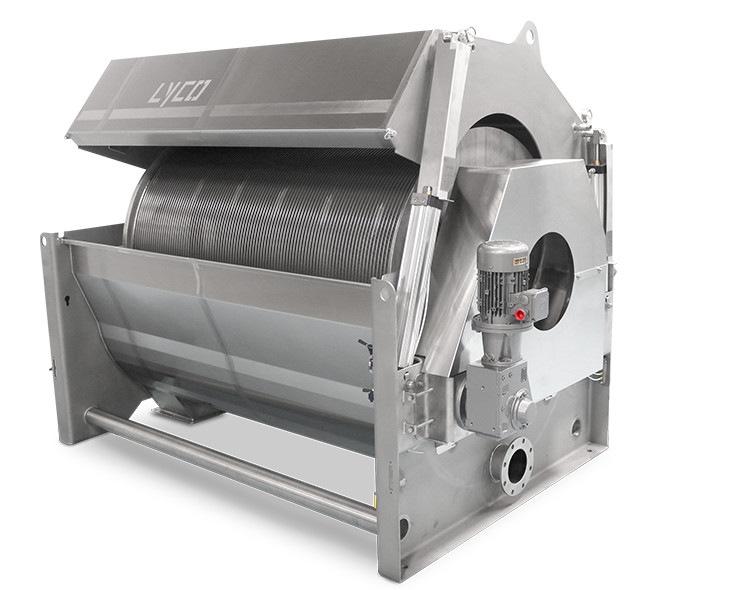

Double Drum Wastewater Screen

Processors can gain significant savings with our Double Drum Wastewater Screen to help reduce industrial waste and increase product recovery. Efficiently performs liquid/solid separation for red meat, pork, poultry, seafood or vegetables. Wedge-wire screens offer greater cleaning efficiencies, or reduce water requirements with an optional, patented Traveling Spray CIP option. More operators rely on Lyco’s Single Drum Wastewater Screen than any other type. Cast Stainless running rings last forever.

-

Single Drum Wastewater Screen

Processors can gain significant savings with our Single Drum Wastewater Screen to help reduce industrial waste and increase product recovery. Efficiently performs liquid/solid separation for red meat, pork, poultry, seafood or vegetables. Wedge-wire screens offer greater cleaning efficiencies, or reduce water requirements with an optional, patented Traveling Spray CIP option. More operators rely on Lyco’s Single Drum Wastewater Screen than any other type. Cast Stainless running rings last forever.

-

Sanitary Zero Maintenance Screen

Lyco Manufacturing takes reliability to the next level with its Sanitary Zero Maintenance Screen design, eliminating trunnion wheels and bearings. The maintenance-free design removes the need for routine lubrication of the bearings. Lyco is known for making the most robust rotary screens in the industry. As with any machinery, chain and sprocket drive systems still require routine lubrication to ensure optimal performance.

-

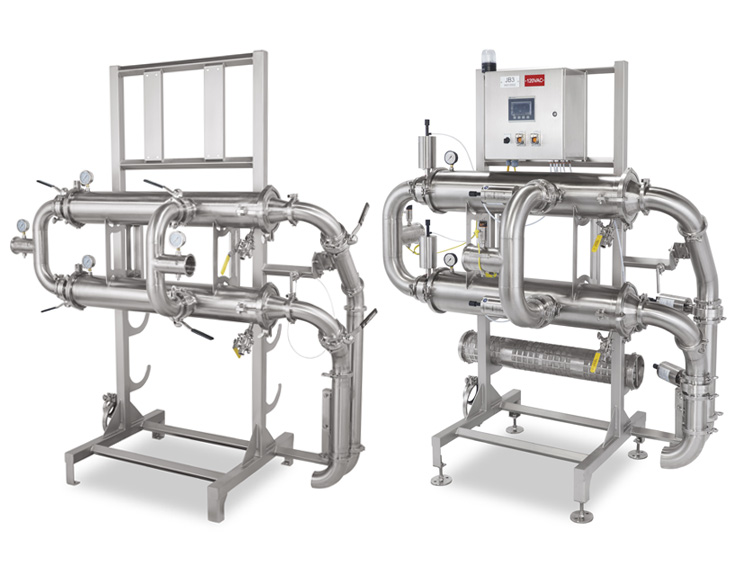

Water Reuse System

Lyco’s Water Reuse System can save money, cut cleaning and maintenance time, and reduce consumption of water resources — up to 15 million gallons per year. In poultry plants, this revolutionary system removes solids so that water can be re-used and sent back for prior processing steps. The system’s small footprint makes it ideal for many water reuse applications. A 200 GPM saving can return more than $150,000 a year.

New Sanitary Zero Maintenance Screens feature covers that open for full access, Clean-In-Place system with spray balls and rapid-change dual canister filters with automated purging.

Systems are available for 50 gpm – 400 gpm. -

Micro Drum Screen

Lyco’s Micro Drum Screen uses a super-fine mesh screen to remove more solids than standard screens. You can slash DAF chemical and municipal costs while reducing industrial waste, increasing product recovery. Lyco’s Micro Drum removes particles as small as .008″ – 60% smaller than the .020″ particle removal for typical screens. This lowers Biological Oxygen Demand (BOD), Total Suspended Solids (TSS), Total Kjeldahl Nitrogen (TKN).

-

Stationary Screen

The Lyco Manufacturing Stationary Screen de-waters products, such as beans and vegetables, or can perform rough screening of wastewater. The wastewater function cleans up pea, bean, corn, potato or meat waste. Sanitary construction and a tilt out screen make cleanup a quick process. High-quality craftsmanship guarantees long life and performance.

-

Sealed Drum Separator

Sealed drum separator features enclosed construction that contains odors, improves liquid recovery and aids in temperature control. Perfect for rendering operations, this system effectively applies heat to extract moisture and separate fat, producing superior crax to the press versus a perk pan, to create rich, granular meals for animal feed or other industrial use. Drum slot spacing offers solids removal down to 0.020 to help reduce insoluble impurities and avoid clogs in screens, nozzles and other equipment further down the processing line. Captures a greater amount of solids to reduce waste and increase product recovery.

-

External-Flow Screen

Lyco Manufacturing has more than 50 years of industry-leading experience manufacturing screens and other food processing equipment. We have an outstanding reputation for manufacturing innovative, rugged machinery, used by 50 of the top 100 food companies in North America. The state-of-the-art design of the Lyco External-Flow Screen uses the same advanced technology and precision manufacturing to help our customers improve their operations.

-

Dual Canister Filters

Lyco’s innovative dual-canister system provides uninterrupted production, even through a filter foul or plug. Flow can easily be rerouted to the clean filter, allowing the plugged filter to be removed and cleaned while production continues.