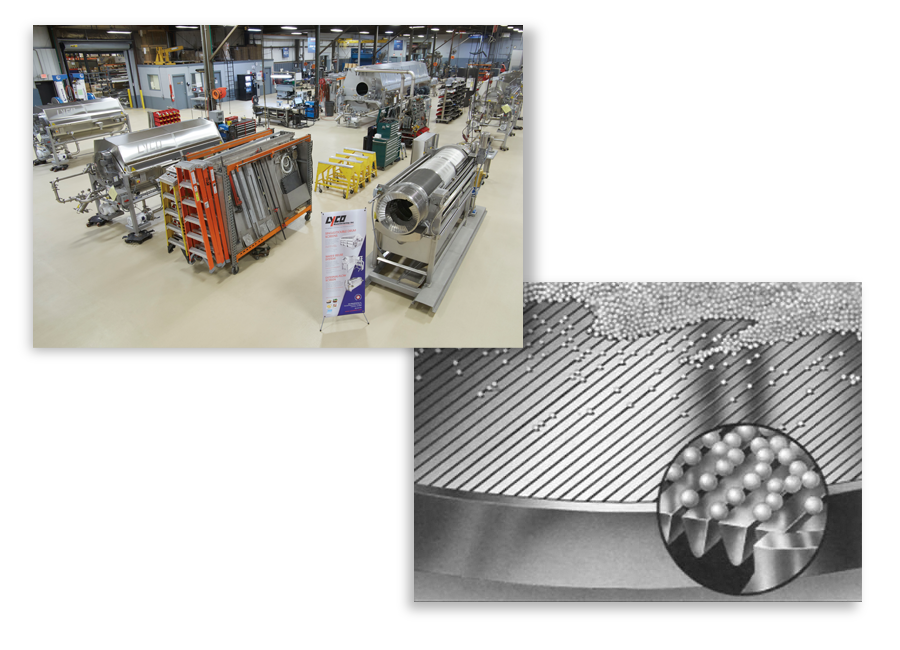

Lyco Manufacturing has over 50 years of experience making machinery for the food industry, and we are known for making the most robust rotary screens in the industry. Our design knowledge guarantees the most efficient and rugged solid/liquids separation screens in the food industry.

• Sanitary Zero Maintenance Screen design eliminates trunnion wheels and bearings

• Zero-maintenance eliminates daily lubricating process

• Lyco has sold more than 2,200 different screens in North America

The Sanitary Zero Maintenance Screen eliminates trunnion wheels and bearings for a maintenance-free design.

|

Lyco was founded in 1980 by the owner and Chairman of the Board, David R. Zittel, who had over 50 years experience in food processing. Lyco prides itself in the longevity of its associates and is measured with many decades of experience with food processing machinery. We’re located in a community of 5,000 people which is 25 miles northeast of Madison, WI, a perfect area to raise a family.

Lyco’s enjoyment and passion is developing the best customer-aligned, innovative food processing machinery in the world. |

• Clean-in-Place System with Spray Balls

• Thermoplastic Discharge Bearing

• Side Opening Doors

• Standoffs eliminate hidden surfaces

• Simple Reliable Drive

• Saves labor costs thanks to the thermoplastic main bearings eliminate lubricants.

• Clean-in-Place systems stop blinding, reduces level of solids, fats, oils, BOD and TSS

• Lowers chemical usage in post water treatment for cleaner discharge

• Cuts industrial waste and creates a secondary revenue stream