Lyco Single Drum Wastewater Screens help processors efficiently separate liquids and solids for red meat, pork, poultry, seafood, french fries, potato chips, fruit or vegetables. More operators rely on Lyco’s Single Drum Wastewater Screen than any other type.

• Gain measurable savings, reduce industrial waste and increase product recovery

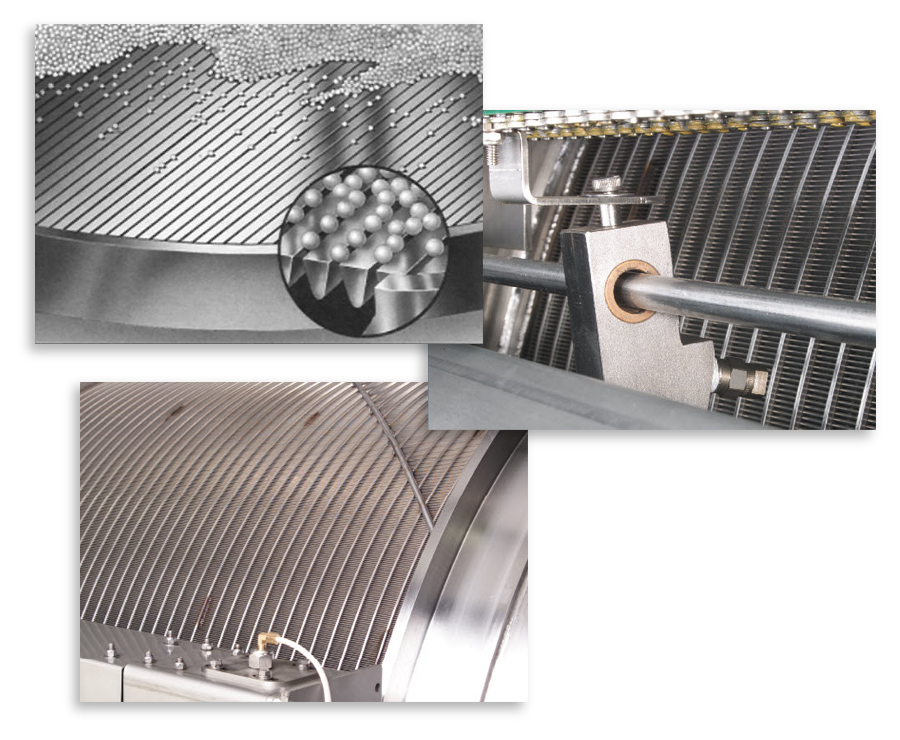

• Wedge-wire screens significantly improve cleaning efficiencies

• Save time, money and water … improve cleaning with patented Traveling Spray clean-in-place (CIP) option

• Lyco has never had a trunnion running ring failure on our designs

• Cut water usage when cleaning with “Patented Traveling Spray”

• Patented “Smart Machine Monitoring System” reduces trunnion failures

• Best versatility due to multiple configurations

• Rugged, precision frame construction reduces maintenance and parts usage

• Wedge-wire screens reduce plugging compared to perforated plate

|

Lyco was founded in 1980 by the owner and Chairman of the Board, David R. Zittel, who had over 50 years experience in food processing. Lyco prides itself in the longevity of its associates and is measured with many decades of experience with food processing machinery. We’re located in a community of 5,000 people which is 25 miles northeast of Madison, WI, a perfect area to raise a family.

Lyco’s enjoyment and passion is developing the best customer-aligned, innovative food processing machinery in the world. |

Our Sanitary Zero Maintenance Water Reuse Screen saved 3.0 Billion gallons of water in 2022.

RUGGED RELIABILITY

Triangular shaped wedge wire is less apt to plug than perforated sheets.

ELIMINATE BINDING

Lyco’s patented traveling spray reduces plugging and binding – uses only 10 GPM.

RINGS NEVER FAIL

Unique, cast stainless steel rings won’t fail like rolled and welded designs.